A massive gun magazine stress test to determine how long magazine springs will last and if we can determine outside variables that impact their longevity.

We set out to test magazines. How long do they last and what can you do as a shooter to help ensure they’ll function properly for as long as possible? In this project, we’re going to give the quick answers up front and then we’ll dive into some of the details about our testing protocol and what we learned.

Spring Test Summary

For about a year, we loaded, unloaded, and function tested thirteen different magazines.

So, How Long Do Gun Magazines Last?

We found the typical pmag would be no more likely to fail in real world trials after a year of solid shooting. In a lab setting, the magazine’s spring cycled nearly 70,000 times before failure. Our lab trials went nearly 15,000 cycles before a factory Glock 17 magazine spring gave out.

Magazines Field Tested

- Magpul Gen 2 Pmag (30 round)

- Magpul Gen 3 Pmag (30 round)

- Magpul Gen 3 Pmag (40 round)

- Amend2 AR-15 Magazine (30 round)

- Lancer AR-15 Magazine (30 round)

- USGI AR-15 Magazine (30 round)

- Smith & Wesson Shield 9mm Magazine (8 round)

- ETS Glock 17 Magazine (17 round)

- Glock 17 Factory Magazine (17 round)

- Magpul Glock 17 Magazine (17 round)

- Glock 17 Factory Magazine (33 round)

- USGI 45 ACP 1911 Magazine (7 round)

- Wilson Combat 45 ACP 1911 Magazine (8 round)

I’m sure you’ve heard someone ask or even wondered yourself if it’s bad to leave your magazines loaded for long periods of time. On the opposite end of the spectrum, there’s also the question of whether or not the actual use of loading and unloading the magazines is really what negatively affects their longevity.

So, we tried to get some answers. For each magazine, we introduced eight different variables included in our testing set.

Variables for Each Magazine Set

1.) Loaded to full capacity and stored in a climate controlled safe

2.) Loaded to full capacity and stored in an outdoor shed with temperatures exceeding 100 degrees with high variability

3.) Stored unloaded in a climate controlled environment

4.) Stored unloaded in a high-variability outdoor shed

5.) Loaded half way and stored in a climate controlled safe

6.) Loaded to capacity, stored in a climate controlled safe and loaded/unloaded five times bi-weekly

7.) Loaded to capacity, stored in a climate controlled safe and loaded/unloaded fifteen times bi-weekly

8.) Loaded to capacity, stored in a hot shed and loaded/unloaded fifteen times bi-weekly

Our Process

Every week for for about 6 weeks, we took the magazines to the range and field tested their function. We fired one round every two seconds in an effort to mimic a “real world” shooter’s use of the magazines in non “SHTF” times. We documented all failures and used a digital force gauge to measure any change in spring strength or resistance.

After about ten months, hundreds of hours, and thousands of rounds we learned… basically nothing!

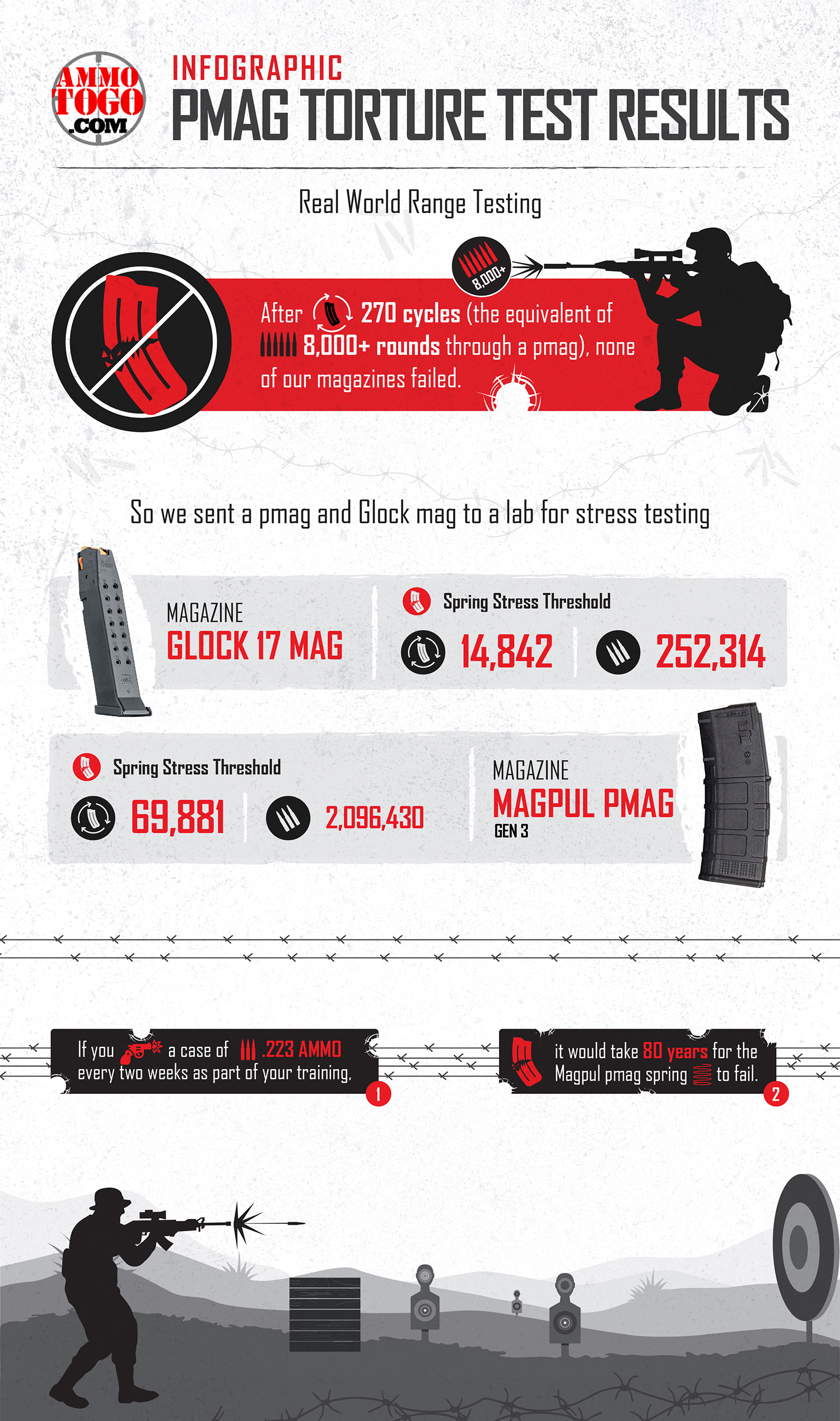

After 270 cycles (the equivalent of 8,000+ rounds through a pmag), none of our magazines failed. The force gauge we used to measure spring resistance didn’t show consistent variability in any of the 104 magazines we tested.

The biggest takeaway from our manual testing was that Magpul’s Pmags showed springs that loosened over the course of our cycling. In many cases, the springs put up 20-25% less resistance after going through our course of testing. But it didn’t matter when it came to function. The magazines all performed flawlessly when field-tested at the range.

So, having no real failures as a result of a ton of trigger pulls we got frustrated. Next, we got angry. Then, we got an idea.

Getting A Lab’s Help

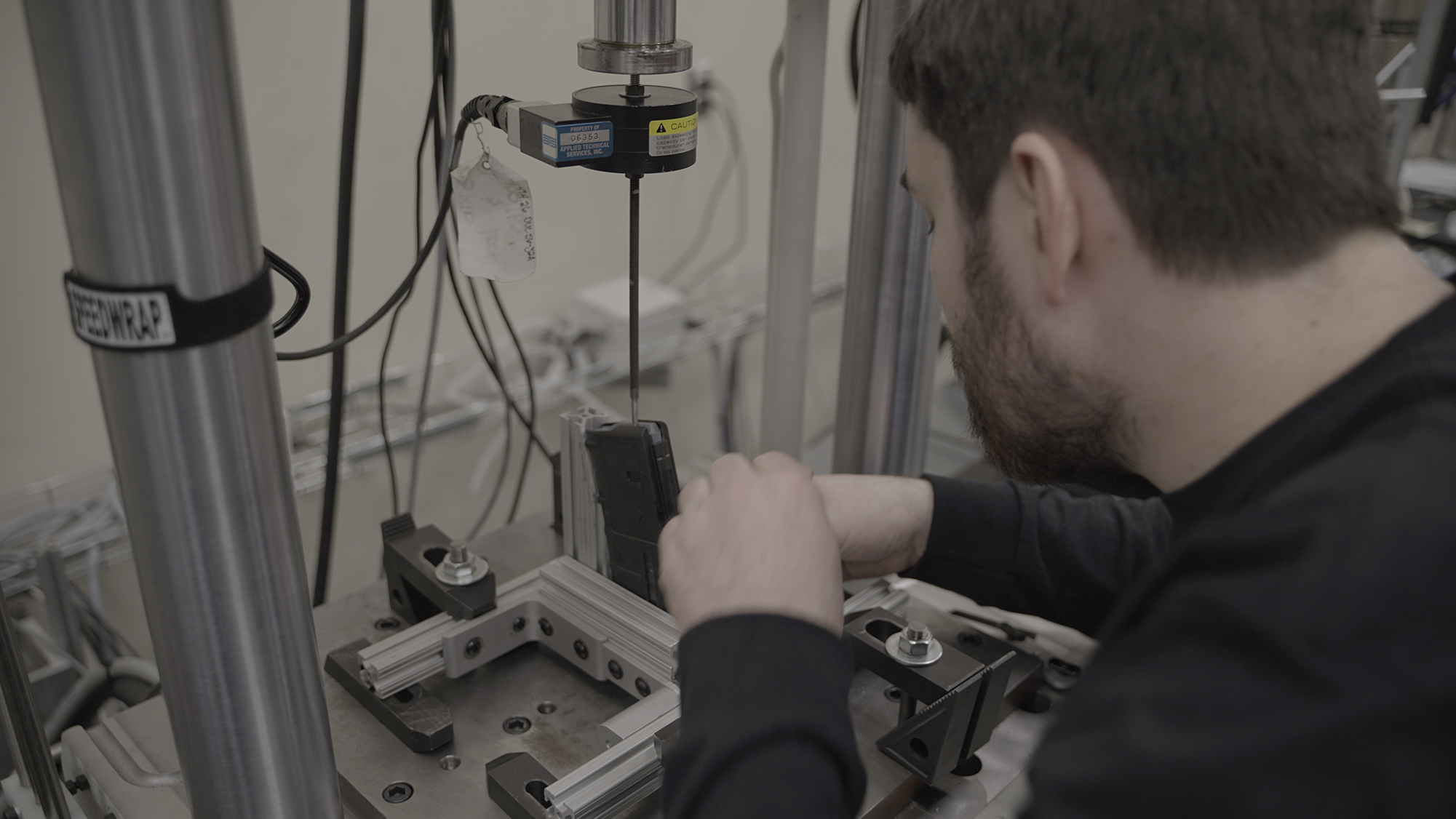

We called some friends at a testing laboratory near Atlanta, Georgia and decided we were going to make a magazine put in the work until it could no longer function.

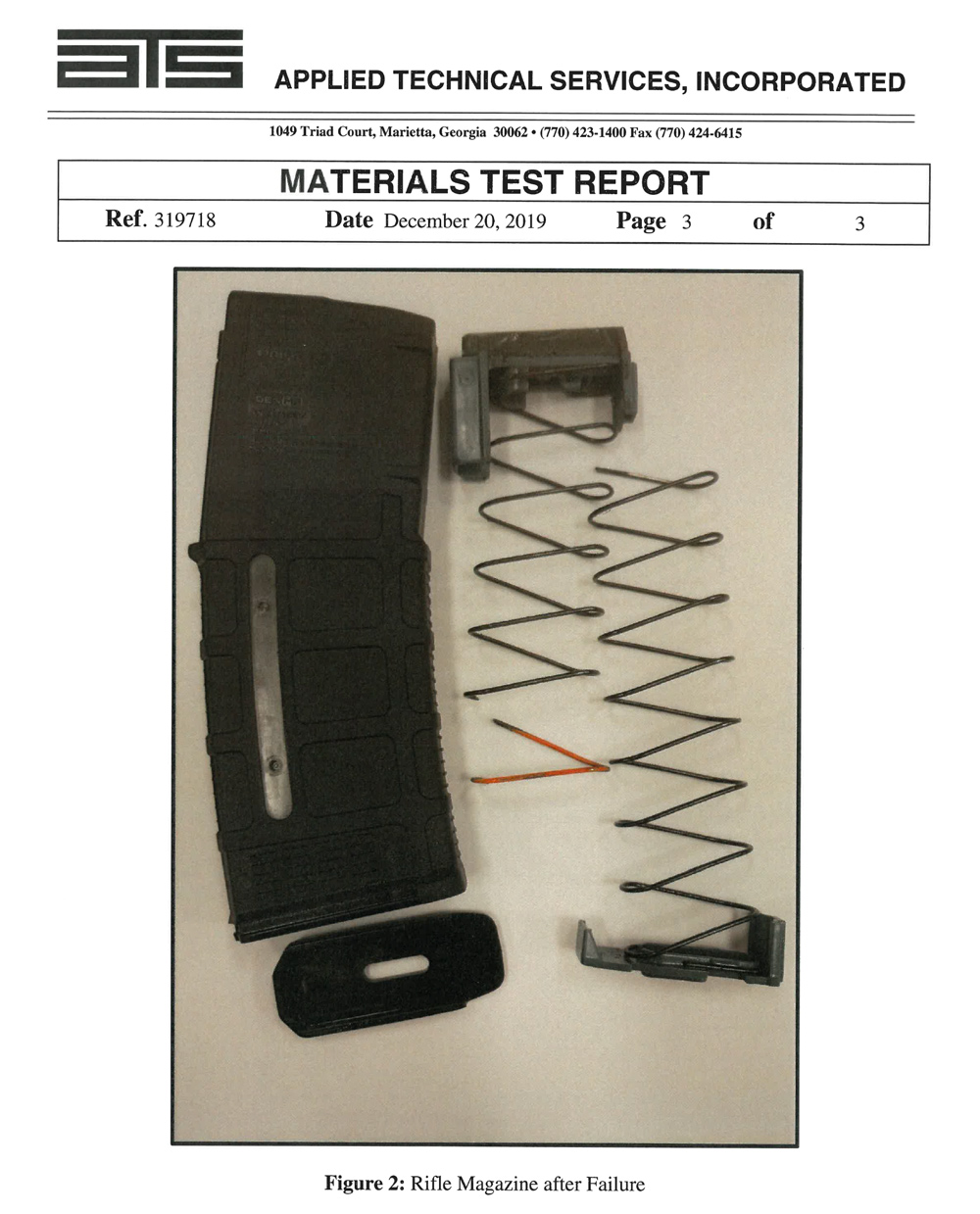

We gave Applied Technical Services a Glock 17 magazine and a 30-round Magpul pmag. Due to the cycling mechanism on their equipment, we were forced to modify each magazine’s follower. (The molded cartridge shape on a typical follower wouldn’t allow our compression rod to push down properly on the spring.) So, the lab welded a special piece to attach to the magazine follower that mimicked the shape of a round of ammo.

The lab crew put the mags in place, turned the machines on, and then waited for something to fail.

When The Magazines Failed

| Magazine | Cycles | Round Equivalent |

|---|---|---|

| Glock 17 Mag | 14,842 | 252,314 |

| Magpul Gen 3 Pmag | 69,881 | 2,096,430 |

As you can see, it took quite a while for anything to go wrong when isolating the springs themselves.

In the case of the pmag, if you fired a case of .223 ammo every two weeks as part of your training, it would take 80 years for that magazine spring to fail.

Where The Lab Test Comes Up Short

Of course, real world shooters run into issues that we didn’t test in the lab. Those are the issues our initial protocol tried to answer (dirt/debris, heat/storage, etc.) We weren’t dropping magazines to the ground, running into things, reloading in a hurry and other issues that could cause wear-and-tear. None of our mags fell from a helicopter or were run over by a tank!

However, based on the limited data we have on how AR-15 and other gun owners train, we believe our initial field testing regimen was more strenuous but still in-line with what a “typical” self-defense shooter’s would be.

After all of the effort, time, and money we poured into this project, we realized one very important thing: It’s incredibly hard to wear out magazine springs.

Want more? Read on to hear all the nitty-gritty about our field tests.

Detailed Data from Our Field Tests

We thought after about a year of rigorous cycling and shooting we’d see results. I mean, we had a set of mags we stored in the southern equivalent of a swamp (a backyard shed.)

Every two weeks, we gathered resistance data using this Andilog Centor Easy, Graphical Force Gauge.

Here’s a sample of all the data. In this case, it’s our resistance testing from Magpul’s Gen2 30 round Pmag.

| Test Subject | Day 1 | Day 15 | Day 29 | Day 43 | Day 57 | Day 71 | Day 85 | Day 99 | Day 113 | Day 127 | Day 141 | Day 155 | Day 169 | Day 183 | Day 197 | Day 211 | Day 225 | Day 239 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mag A | 11.604 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 8.646 |

| Mag B | 11.354 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 8.356 |

| Mag C | 10.575 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 8.506 |

| Mag D | 10.215 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 8.366 |

| Mag E | 11.815 | 11.495 | 10.485 | 10.345 | 9.346 | 9.136 | 9.296 | 9.356 | 9.176 | 8.736 | 9.785 | 9.086 | 9.276 | 8.329 | 8.506 | 8.516 | 8.726 | 8.776 |

| Mag F | 12.114 | 11.825 | 10.055 | 8.826 | 10.405 | 10.015 | 9.566 | 9.076 | 9.935 | 8.726 | 8.587 | 9.775 | 8.596 | 8.726 | 8.706 | 8.326 | 8.556 | 8.856 |

| Mag G | 11.984 | 11.595 | 9.269 | 10.145 | 9.286 | 9.975 | 9.705 | 9.825 | 9.765 | 9.236 | 9.795 | 9.246 | 8.876 | 8.324 | 8.716 | 8.826 | 8.585 | 8.526 |

| Mag H | 11.314 | 11.525 | 9.286 | 8.996 | 9.356 | 10.075 | 9.546 | 8.946 | 9.406 | 9.754 | 9.456 | 8.576 | 8.686 | 8.726 | 8.686 | 8.426 | 8.884 | 8.776 |

You can view all our data for all magazines in this downloadable .pdf file by clicking here.

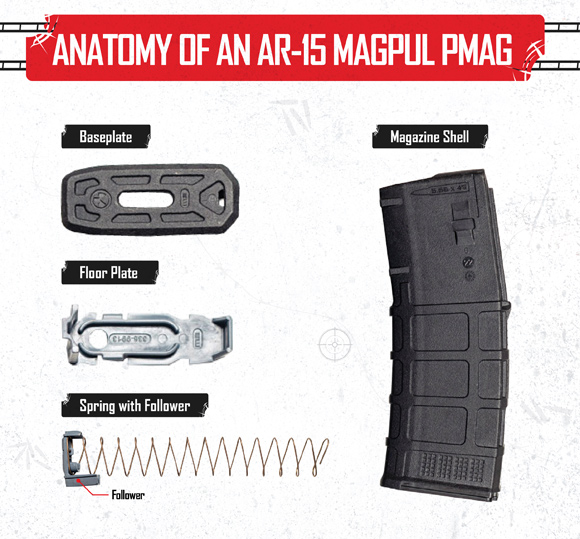

Basic Parts of a Firearm Magazine

While the selection and quality of magazines have definitely improved over the years, the basic science behind magazine design has essentially remained the same. A detachable box magazine’s primary function is to feed ammunition into a repeating firearm by the force of a compression spring. Although a somewhat simple design, a magazine can also be a frustrating source of malfunctions when operating a firearm.

Magazine Springs

The springs found in most box magazines are commonly known as compression springs. These springs provide resistance when a load is applied.

When ammunition is loaded into a magazine, the spring stores energy, which is then used to chamber an individual round by the action of the firearm.

In recent years some popular brands have fallen to the wayside, but it seems that there are new firearm and accessory companies popping up more and more these days.

While this is a welcome sight, consumers need to be cautious that their magazines actually come from a reputable manufacturer.

Below is a list of some of the industry leaders in magazine springs:

- Mec-Gar

- Wolff Gun Springs

- Magpul

- ETS

- Glock

- Wilson Combat

Magazine Follower

The compression spring does most of the work in a magazine, but it does need help guiding the ammunition and keeping everything in-line. This is where the magazine follower comes into play. A follower is typically made of polymer or metal and is used as a platform for the spring to push against the ammunition. This device keeps ammunition upright and organized inside the magazine housing.

Magazine Housing

The magazine housing keeps the spring, follower, and ammo all contained in a nice neat little package. Housings come in all different shapes, sizes, and materials, depending on your firearm and caliber setup.

Some firearms, such as bolt actions, can use what’s called an internal or fixed magazine. These magazines are usually loaded through the action, one round at a time and are usually permanently built into the firearm itself.

Magazine Baseplate

The baseplate is what keeps the spring, follower, and ammo from spewing out the butt-end of the magazine. Most box mags have removable baseplates to allow for easy disassembly and cleaning, while others have fixed baseplates, like most USGI 1911 mags.

A popular modification these days is to purchase a baseplate that will increase the overall capacity of your magazine. Some extended baseplates can also serve as a grip extension for smaller profile handguns. It is recommended however to use an aftermarket spring with any baseplate extensions, as the OEM spring may not be long enough to provide the resistance to successfully cycle ammunition.

—————————————————————————————————————————————————————

Common Magazine Malfunctions

There are many ways a magazine can be the culprit for malfunctions. While these devices are relatively simple in design, they are an integral part of a firearm.

Wear and Tear

Shooters that frequently train or work with their firearms will likely experience some damage to their magazines over time. The issues can stem from accidental drops, tactical reloads, or even overexposure to the elements. This wear and tear from extended use can create issues down the road if not properly addressed. Identifying and replacing cracked or damaged followers and baseplates can help mitigate common malfunctions.

Damaged or Faulty Ammo

Even in a brand new magazine, improperly maintained ammunition can cause headaches for you. Damaged cases, primers, and even rust can all cause your firearm to malfunction. Check out our article on proper ammunition storage to see how you can easily prevent malfunctions by improving your ammo storage habits.

Firearm Magazine Maintenance

Sure, your magazines are pretty durable, but do you still need to clean them? Of course, you do! Outside factors such as carbon fouling, dirt, and even human sweat can all negatively impact the performance of your mags.

Unless you carry your concealed firearm in a zip-lock baggy, there’s a good chance that sweat will find its way into your magazine. The salts from human sweat can wreak all sorts of havoc on metals, especially the magazine spring.

If you practice with your mags at the range, carry them on duty, or even bring spares in the field when hunting, there is a good chance that they get dirty enough to warrant a good cleaning every now and then. All it takes is a small clump of dirt, tiny rock, or other foreign objects to get lodged in your mag to cause a malfunction.

Rotation Schedule

When using magazines for defensive or tactical purposes, it’s a good idea to always have spares on hand. If you don’t have time to routinely sit down to clean and assess your mags, implementing a rotation schedule can come in handy. Some law enforcement agencies across the U.S. even have a rotation schedule included in their standard operating procedure.

Spring Stretching

DO NOT under any circumstances stretch your magazine springs. You will not gain any additional “springiness” by doing this. Compression springs are not meant to be stretched back to a pre-set length. If anything, you are actually weakening the spring and causing unnecessary stress on the individual coils.

Friends don’t let friends stretch their springs.

Storage Conditions

Shooters that improperly store their firearms for long periods of time can also run into a myriad of issues. Magazines left in non-climate controlled storage can experience huge temperature swings, exposure to moisture, and other unexpected problems.

There are multiple reports of magazines failing to retain the loaded ammunition due to extreme temperatures. For example, this was observed multiple times in Iraq when the US Army used polymer magazines. The polymer feed lips would warp from the heat, causing the ammunition to be ejected from the magazines due to the pressure of the follower and spring. This issue was remedied by using magazines that had metal feed lips that would not warp when exposed to hot temperatures.

Generally speaking, shooters believe magazines left in climate-controlled storage settings fare better and can be more reliable in the long run. While this is an ideal scenario, we understand it’s not always an option. Further, our real-world testing for about a year couldn’t back-up this commonly held belief.

—————————————————————————————————————————————————————

Downloading Your Magazines

Storing Fully Loaded vs. Half-Loaded

Does leaving your mags loaded do more harm than unloading them and reloading them daily, weekly, or even monthly? What counts as an extended period of time?

In some circles, there is an argument for loading magazines just shy of their full capacity. This method is also known as down-loading. Some claim it will prevent overall spring fatigue, spring set, and other magazine-related malfunctions.

Magazine Spring Science

- Creep

- Elastic Limit

Metal Yield Stress

Yield strength is the point of minimum stress under which material will permanently deform, whereas tensile strength describes the point of maximum stress that a material can handle before fracturing.

Spring Set

According to Springipedia, “When a compression spring is compressed and released, it is supposed to return to its original height and, on further compressions, the load at any given point should remain constant at least within the load limits specified. When a spring is made and then compressed the first time, if the stress in the wire is high enough at the point the spring is compressed to, the spring will not return to its original height (i.e., it will get shorter). This is referred to as “taking a set”, or “setting”. Once the spring is compressed the first time and takes this set, the spring will generally not take any significant additional set on subsequent compressions.”

There are two common solutions that magazine manufacturers take into consideration when dealing with spring set. One way is by making the spring slightly longer than needed then compressing it to take an initial set before the magazine is fully assembled. Once the spring is “preset” it will then meet the correct height and load requirements for its final application.

Although, presetting springs can be a costly and time-consuming process. Another alternative is for a company to design and sell their magazines fitted with springs that are slightly longer than their final height. The idea here is to let the customer’s use of the magazine set the spring. So while you may observe a spring taking a set from constant use, keep in mind that the engineers may have intended for that to happen.

—————————————————————————————————————————————————————

Spring Tension Testing

We set out to test how changing the tension of the magazines while they are stored would impact performance. Again, after about a year and thousands of rounds, we observed no measurable difference in performance. If you’re curious to see the data anyway, please read on.

Testing Results

So, does partially loading a magazine actually help increase its lifespan? According to our data, NO!

| Magpul Gen 2 Pmag | Magpul Gen 3 Pmag | S&W Shield 8-Round | Glock 17 Factory Mag | |

|---|---|---|---|---|

| Left Loaded | 10.7 | 10.7 | 7.0 | 5.8 |

| Left Unloaded | 10.8 | 10.5 | 7.0 | 6.1 |

| Loaded Half-Way | 11.2 | 10.6 | 6.9 | 5.7 |

After 10 months of identical use and identical storage conditions, both the Gen 2 and Gen 3 Pmags we loaded to a full 30 rounds had almost identical spring resistance values to those we left unloaded and those we only loaded half-way. Other AR-15 magazine brands, like Amend2, produced similar test results. Our Glock 17 and Smith & Wesson Shield magazines were similar.

While down-loading seems to make sense as a simple solution, it is largely misdirected. According to our data, down-loading does not give you any significant advantage when it comes to preserving the life of your springs. Many common firearm and magazine malfunctions can actually be attributed to other causes. User errors, specific firearm designs, and even certain ammo loads have all been known to be the root cause of most malfunctions, all before the blame can be placed solely on the magazine springs.

Your magazine springs also do not need to “rest”. They do not need a vacation, nor a coffee break. The well-educated engineers behind the designs knew what they were doing. If you have a 30 round magazine, it is literally designed to hold 30 rounds. Simple as that.

Based on industry experts feedback and our tests results, if you’re not fully loading your mags, you are only limiting yourself to the ammunition you have available to you at a moment’s notice.

Conclusions

Common wear and tear from everyday use is more likely to degrade the overall quality of a firearm magazine than the spring failing on its own from being loaded to full capacity and stored for long periods of time.

Since it’s not economical for a shooter to monitor their spring’s quality with force gauges, the only true way of knowing if your magazines are functioning reliably is from actual use during training.

So, unless you’re part of the group of individuals that actually shoots thousands of rounds down range on a weekly basis for training or completion reasons, the whole issue of worrying about the lifespan of your magazine springs is somewhat trivial.

Other, Larger Concerns

If you’re prepping for a SHTF situation, simply load your mags and set them aside. You can now use all the extra spare time figuring out if you want a Menu 18 beef patty or Menu 14 Spicy Penne Pasta MRE!

As for mags, there are many other factors to consider before worrying about magazine spring failure. First, address the overall quality and cleanliness of your firearm, magazine housing, guide rod, buffer tube spring, ammunition choice, the list goes on. Magazine springs are relatively cheap items that can ultimately fail, just like any other man-made item before it. Luckily, they are easy to replace once identified as the cause of a malfunction.

For those out there that handle their firearms on a daily basis, carrying reliable magazines should be a top priority.