A torture test of sorts for the two best selling ammo cans on the market! What do you get when you buy American made ammo cans vs. Chinese ammo cans?

Ammo cans are popular for storing and protecting ammunition. They’re great for keeping rounds sealed away from moisture and reducing the chances of damage.

Two options, the American-made Blackhawk! M2A1 and the Chinese-made GunMate .50-caliber can, are popular right now. The Chinese version, like many made-in-China products, comes with a slightly lower price. But is it worth the cost savings?

To find out the differences we put the two cans through a series of tests that will demonstrate the strength, quality, and effectiveness of the cans.

American vs. Chinese Made Ammo Can Comparison

First Impression: Physical Appearance and Feel

Paint

Both of these cans have a dark green finish, although the GunMate (Chinese) ammo can has a slightly darker, deeper green than the Blackhawk! can, which has more of a toned-down, lighter green by comparison.

The most noticeable difference is the overall finish, as the Chinese version has a sleek sheen; when you hold it near a lamp, you can see the reflection of the light, almost in the way you’d see a light reflecting off a finely-polished desk. The American version, however, has a matte finish. It doesn’t have the same sheen. Instead of a sleek, polished look, it has more of a non-reflective finish that appears more utilitarian than the shinier Chinese can.

It’s possible that the dull non-reflective coating may be by design, as these are military-spec cans and reflection is not a desired trait for most military equipment.

If you want a shiny ammo can, the Chinese product would be more appealing; if you want a can that looks more like a military product, the American version would be preferred.

Stackable

Both of these ammo cans fared poorly when it comes to stacking. They are designed to be stacked so you can purchase multiple cans and stack them for better storage efficiency. However, we found that both had a slight wobble when stacked on the same can. (American-made stacked on American-made, for example.) This leads us to believe that if you were to stack five or six high, the tower would be fairly unstable and may topple.

Feel

To be honest, feel is completely subjective and unscientific. We took no measurements on feel, nor did we conduct any real research. All we did was hold the can in our hands, toss it around, knock on the outside, and swing it by its handle; this may not be the most scientific strategy, and leaves room for subjectivity, but it can tell you a lot about the can itself.

When handling the two cans, it seems that the American version has a denser, sturdier feel. When you tap the outside of the can, either on the sides, bottom, or top, it seems to bring a duller “thud,” while the Chinese version has more of a hollow “ding.” It also feels that the American version has a slightly thicker metal, which may be affected by the finish.

Craftsmanship

We also noticed that when you shake or swing the American-made can, there is a lot less noise, mostly because the U-shaped handle at the bottom on the side does not move by itself. Both have U-shaped rods near the bottom of the lid handle. On the Chinese version, this rod swings freely, so it rattles against the body of the can. On the American version, the rod is firmly secured and does not move without manipulation, meaning there is no rattle when the can is shaken.

When fumbling with the cans, we were able to slip the lid of the Chinese version off the can itself. Essentially, it slides off the rods that hold the hinge. This could be a useful for some users who want to take the lid off so they can easily access the ammo without the lid hanging over the side. The lid came off the American version, but not without significant effort. Once the lid on the American can came off for the first time, it was easy to take off, as if it had slipped loose.

Overall, the American version simply has a sturdier, more compact feel. It feels tighter, denser, and stronger. Whether it actually is stronger, we will try to determine in testing.

Physical Testing: Scratch, Impact, and Crush

To test the durability and strength of the ammo cans, as well as the quality of the paint and finish, we put the ammo cans through a variety of tests with various tools. We scratched, hammered, gouged, and crushed the cans to see how well they hold up under significant abuse.

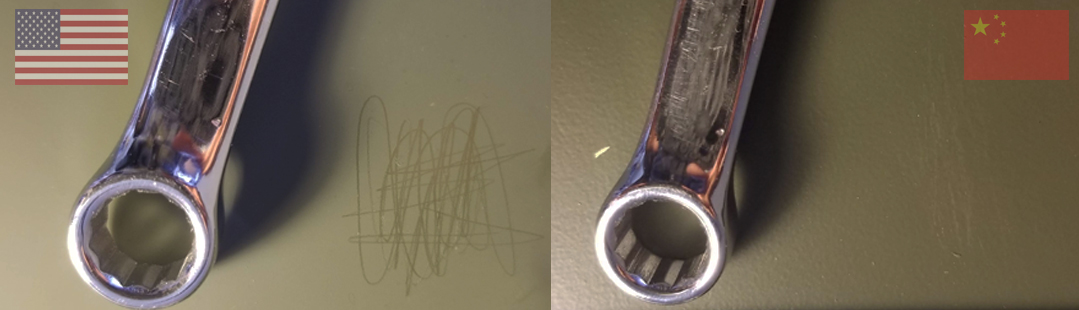

Wrench (Box End) Test

First, we stated with a dull object: the box (ring shaped) end of a small wrench. We scraped the round edge against the can to see what damage we could create. In this case, we found that the Chinese can had slightly-visible scratches, which were only clear when light hit the can at the proper angle. The American can, however, showed clear dark scratches from the dull metal object.

Winner: Chinese

Needle-nose Pliers Test

Next, we gave the cans a scratching with the end of a needle-nose pliers, which had a distinct edge and was able to make deeper scratches. In this case, the rugged quality of the American can began to show. On the American can, there were very visible scratches left by the pliers, but on the Chinese can, it was easier to make deep gouges with the needle-nose.

Winner: American

Knife Test

Using a knife, we both scratched and cut at the cans. In this case, the results seemed similar, as both left highly visible marks in the finish.

Winner: Draw

Light Hammering (Side)

Using a small hammer, we pounded at the side of the cans, being careful to use similar force and similar location for all impacts. On the American can, the hammer left a small mark showing the outline of the hammer’s nose, and there was a slight dent that, while not as visible, could be felt when running a hand over the point of impact.

The Chinese can, however, actually had no noticeable dent in can, but there were marks roughly the same as the American product. (The Chinese can seems to be more flexible. Perhaps this allowed the can to absorb the light blows and not dent.)

Winner: Chinese

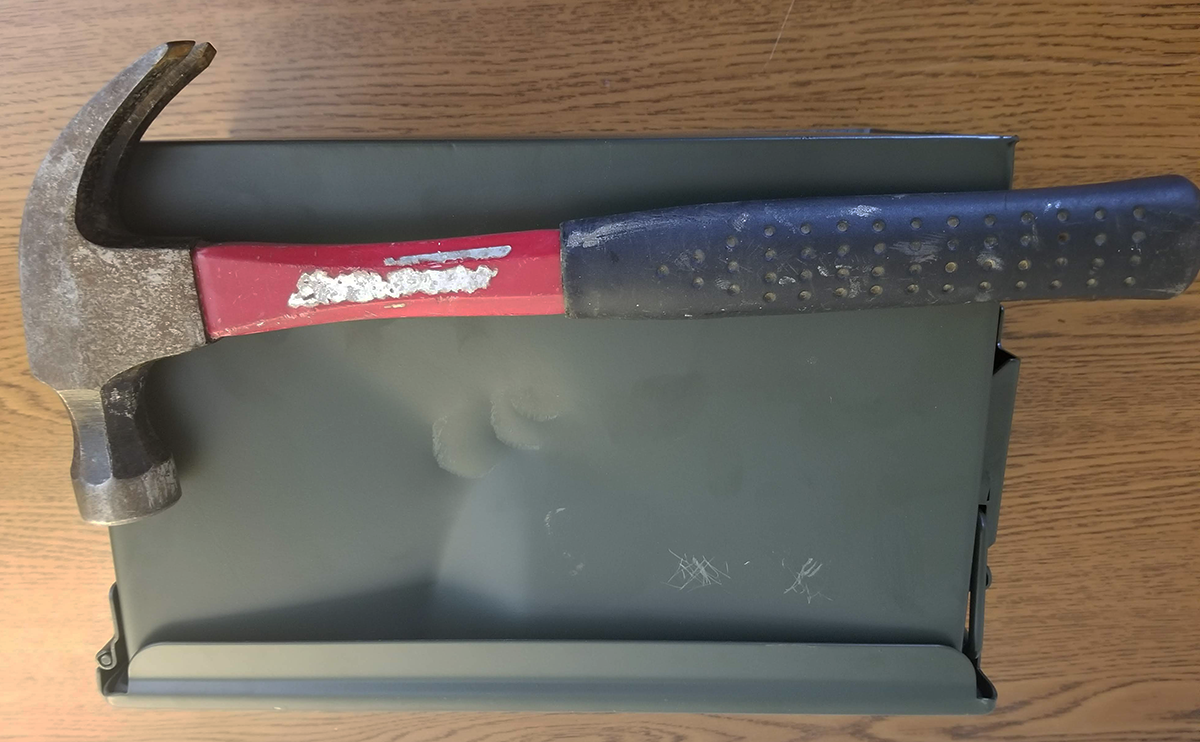

Heavy Hammering (Side) Test

Next, we used a heavier hammer and drove three strong blows into the side of the cans. The results showed that while both cans are tough, they are not indestructible. The American can had a significant bend in the side, forcing the top edge out of sync with the rim of the lid. The Chinese version, however, had major bending that was deeper than the previous product. There may be human inconsistencies at play, but it appears the American version holds up against major denting better than the Chinese can.

Winner: American

Heavy Hammering (Top)

Before putting away the hammer, we turned the cans upright and gave three strong blows to the top of each. Both had light dents, but the Chinese version again appeared to have craters that were slightly deeper. One thing is for sure, the lids of the cans are far stronger than the sides.

Winner: American (narrow victory)

Prying Handle Bracket

Finally, we took the hammer and placed the claw edge under the handle bracket in an attempt to pry off the handle itself, which we couldn’t do with either product. However, while the American version barely bent, the Chinese version saw significant bending in the bracket, as well as cracking in the paint.

Winner: American

Crushing with Vehicle

Finally, we really wanted to see how well these two ammo cans would hold up against some of the heaviest pressure to can apply, so we used a vehicle to drive over them, subjecting the cans to hundreds of pounds of pressure, testing, once and for all, how tough these two can really are.

This test was simple. We placed the fresh cans, which had not been hammered or scratched, in front of a vehicle and slowly drove over them. The cans were placed on their side, with the bottom section facing the wheel.

We tested the Chinese made can first. As you’d guess, it was crushed significantly by the vehicle. As we drove over it, we could hear an audible crumpling from the can, telling us that the can succumbed to the weight of the vehicle. Before testing, this can had a bottom width of 5-5/8 inches, but once if was crushed by the vehicle, it had a U-shaped base that bottomed out at about 2.5 inches.

The American can, while crushed, seemed to fare better. It crumpled like the Chinese ammo can, but it only dropped to about 4 inches.

To be fair, the ammo cans were both effectively destroyed. However, the results showed that the American version does seem to have a stronger build compared to the Chinese-made ammo can.

Winner: American

Overall Conclusion from Scratch, Impact, and Crush Test

After putting both cans through a series of rugged tests, we can reasonably say that both have good construction, quality paint, and quality materials. However, it seems that while the American version may show more visible scratching from the light abuse it will receive (tossed around in truck bed, for example), it will also have a better chance of keeping its overall structural integrity. It also has a stronger profile and clearly holds up better against impact from blunt objects, as well as crushing from heavy equipment.

The American-made ammo can may not be prettier, but it will hold up. The Chinese version, however, seems to hide scratches better and (perhaps because it’s more flexible while the American version is rigid) seems to resist light denting.

Water Testing of Ammo Cans

The Case for Waterproof Storage

One of the most important qualities, some would argue the most important quality, of an ammunition can is to lock out moisture.

As you likely know, when ammunition is exposed to water, bad things happen. The moisture can impact the structure of the casing, the quality of the bullet, and, if moisture seeps into the propellant, the reliability of firing. There are plenty of stories about people cautiously loading wetted ammunition and having no issues. But there are also times when good ammo stored in a water-damaged basement was rendered useless. Plenty of hunters have had rusty hulls on their shotgun shells after exposure to moisture. Today’s modern ammunition is less susceptible to moisture, but that doesn’t change the fact that watertight storage remains important for all gun owners.

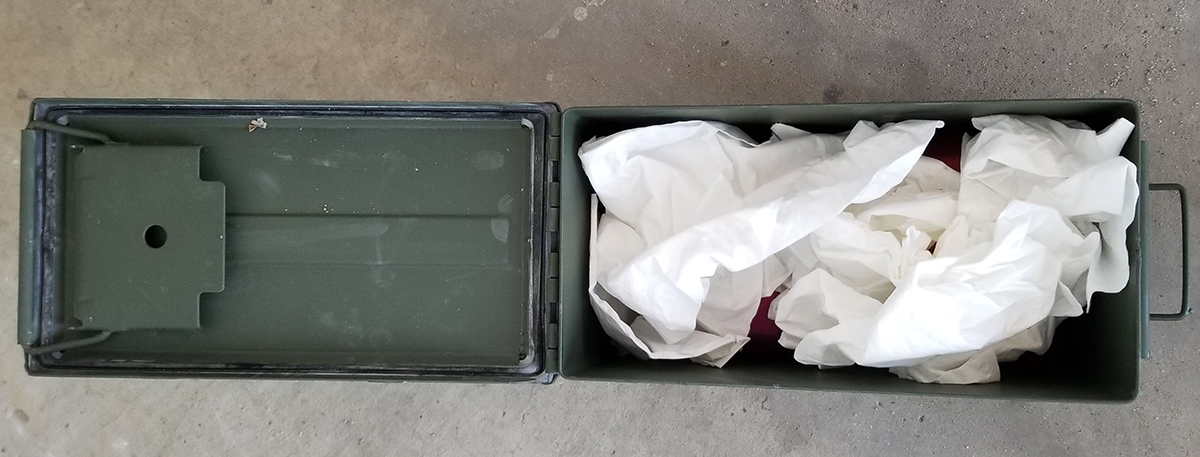

Water Test #1: Complete Submergence

We used two five-gallon buckets filled with water as our submergence tanks to test the cans. We wanted

30 Seconds

After 30 seconds of submergence in water, we found completely dry interiors. There was no noticeable moisture on the tissue paper placed in either can.

1 Minute

Same result: no moisture whatsoever.

30 Minutes

Also no moisture.

1 Hour

Same result after one hour: no wetness found in the cans.

Overnight (12 Hours)

We dipped the cans into the water for times up to an hour and observed absolutely no noticeable leak into the cans. Then, we decided to go for broke and submerge the cans for a 12-hour period. Once again, neither the American version not the Chinese version showed any signs of leakage.

Results from Water Testing

There is little to describe here. Both cans performed perfectly in our tests, locking out moisture for a period up to 12 hours. It seems likely that both cans could have kept water out for period well beyond the 12-hour mark.

If water-resistance is your top priority for the storage of your ammunition, either one of these cans will serve you well.

Rust: An Accidental Result of Water Testing?

After submerging the cans in water, we did notice one inadvertent result. A day after we pulled the cans from the water, we noticed a rusty orange coloration near the joints of the Chinese-made ammo can. It appears that this was rust powder from areas where the water was able to reach the metal. We didn’t see that same orange coloration on the American-made can.

This is completely speculative, but it seems that Chinese can could have rust problems, potentially harming the structural strength of the can throughout the years. It’s also possible that this rust powder could work its way onto the ammunition.

This might not impact the effectiveness of the ammo, but you don’t want to load rust-powdered cartridges into your weapon, as it would damage the internal components.

Handle Test: How Much Weight Can It Hold?

For one last test, we wanted to gauge the strength of the handles. We wanted to make sure they will hold up against the heavy pressures that come with a full load and weight of ammunition. To measure the handles we started with relatively light weight. The handles held strong so we quickly moved to heaver weights and longer time periods.

To start, we simply filled the cans with water. Measuring the cans before and after, we determined that when full, the cans hold roughly 13.2 pounds of weight. We suspended the cans by their handles and gave them five minutes; it was clear that neither handle was going to budge; we weren’t coming close to damaging the cans. We decided, therefore, to increase the weight and the timeframe.

To increase the internal weight, we filled the cans with coarse sand, then saturated the sand with water. This water-sand concoction resulted in an internal weight of 29 pounds, but it seemed to make little difference to either can. We suspended them for 20 minutes with no damage, then let the cans sit for an hour and still no change.

In all, it seems that both of these cans have very strong handles that will be able to hold a full load of ammunition for an indefinite period. If handle strength is a concern for your purchase, either one of these ammo cans will perform as you require.

Winner: Draw

American-Made vs Made in China: The Final Verdict on Ammo Cans

When the final results are in, it’s clear that the American-made Blackhawk! M2A1 has stronger materials, a more durable (but less shiny) paint job, and a superior profile.

However, the Chinese can held up well in many tests. If you are serious about purchasing a can that will last for decades (or longer), the Blackhawk! M2A1 is likely your best choice. But the Chinese version, when properly handled, will certainly lock out moisture and protect ammunition from damage.